Product Range & Key Features

- O-Rings

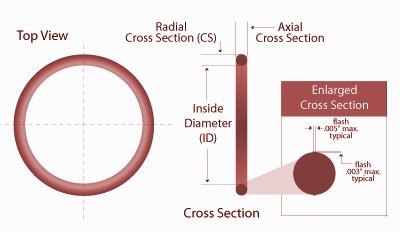

- Features:Circular cross-section, excellent compression set resistance, reliable sealing under pressure.

- Applications:Hydraulic systems, pneumatic equipment, automotive engines, plumbing.

- Gaskets & Washers

- Features:Flat or custom-shaped, vibration damping, chemical resistance.

- Applications:Pipe flanges, machinery housings, electronics enclosures.

- Lip Seals (Radial Shaft Seals)

- Features:Dynamic sealing, low friction, wear resistance.

- Applications:Rotating shafts, bearings, pumps, gearboxes.

- Custom-Profile Seals

- Features:Molded to exact specifications, complex geometries, multi-material options.

- Applications:Aerospace, medical devices, food processing, semiconductor equipment.

- High-Temperature & Chemical-Resistant Seals

- Features:Made from Viton®, silicone, or EPDM, withstands extreme heat/oils/acids.

- Applications:Oil & gas, chemical processing, automotive fuel systems.

Material Safety & Compliance

- Non-Toxic Options:FDA-approved silicone & EPDM for food/medical use.

- High-Performance Materials:

- Nitrile (NBR)– Oil/fuel resistant

- FKM (Viton®)– Extreme heat/chemical resistance

- Silicone– Wide temperature range (-60°C to 230°C)

- Certifications:

- FDA 21 CFR, USP Class VI(food/medical safety)

- RoHS, REACH(environmental compliance)

- ASTM, ISO 3601(industry standards)

Customization Services

We offer tailored sealing solutions to meet exact requirements:

✔ Material Selection (NBR, FKM, silicone, EPDM, etc.)

✔ Precision Sizing (standard & non-standard dimensions)

✔ Special Coatings (low-friction, conductive, or anti-static finishes)

✔ Prototyping & Testing (leak testing, compression analysis)

Maintenance & Care Tips

- Installation:Lubricate with compatible grease to prevent tearing.

- Cleaning:Use mild solvents (avoid petroleum-based cleaners for NBR).

- Storage:Keep in cool, dark conditions; avoid stretching or compression.

- Inspection:Check for cracks, flattening, or hardening regularly.

- Replacement:Change seals if leaks occur or material shows wear.

Conclusion

Our rubber sealing rings provide leak-proof performance across industries, from automotive to medical applications. With strict quality control and customization options, we ensure reliable sealing solutions for your specific needs.

Tags