Product Range & Key Features

- Overmolded Handles & Grips

- Features:Non-slip texture, vibration damping, ergonomic design.

- Applications:Tools, medical devices, sports equipment, automotive controls.

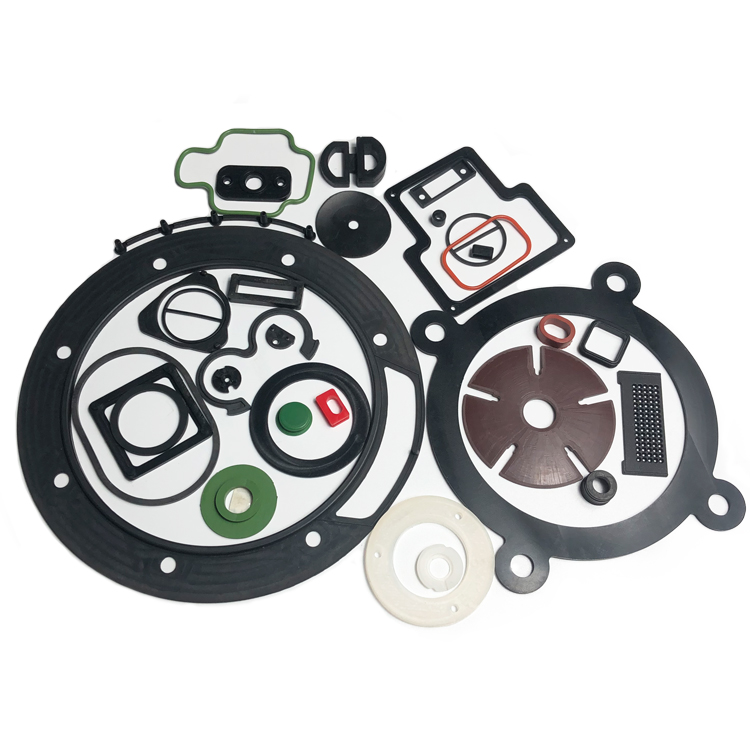

- Seals & Gaskets

- Features:High compression resistance, chemical/weather resistance, airtight/watertight sealing.

- Applications:Automotive, plumbing, industrial machinery, electronics.

- Protective Bumpers & Feet

- Features:Impact absorption, scratch resistance, noise reduction.

- Applications:Electronics, appliances, furniture, medical devices.

- Cable & Connector Overmolds

- Features:Strain relief, waterproofing, enhanced durability.

- Applications:Consumer electronics, automotive wiring, industrial sensors.

- Custom Overmolded Components

- Features:Multi-material bonding, tailored hardness (Shore A to D), color matching.

- Applications:Aerospace, defense, robotics, specialized industrial uses.

Material Safety & Compliance

- Non-Toxic & Skin-Safe:Medical-grade TPE, silicone, and EPDM available.

- High-Performance Rubber Options:Nitrile (NBR), Neoprene, Viton® (for extreme conditions).

- Certifications:

- FDA, USP Class VI(for medical applications)

- RoHS, REACH, Prop 65(environmental compliance)

- UL, ISO 10993(biocompatibility testing)

Customization Services

We provide tailored overmolding solutions to meet exact specifications:

✔ Material Selection (TPE, silicone, rubber blends)

✔ Precision Bonding (to plastic, metal, or other substrates)

✔ Color & Texture Customization (molded-in logos, anti-slip patterns)

✔ Prototype-to-Production Support (DFM analysis, rapid tooling)

Maintenance & Care Tips

- Cleaning:Use mild soap and water; avoid harsh solvents that may degrade rubber.

- Storage:Keep in a cool, dry place away from UV exposure to prevent hardening/cracking.

- Inspection:Check for wear, tears, or loss of elasticity periodically.

- Replacement:Overmolded parts in high-friction applications should be replaced when surface degradation occurs.

Conclusion

Our overmolded rubber components deliver unmatched durability, safety, and functionality across industries. With advanced manufacturing techniques and strict compliance standards, we ensure reliable performance in even the most demanding environments.

Tags