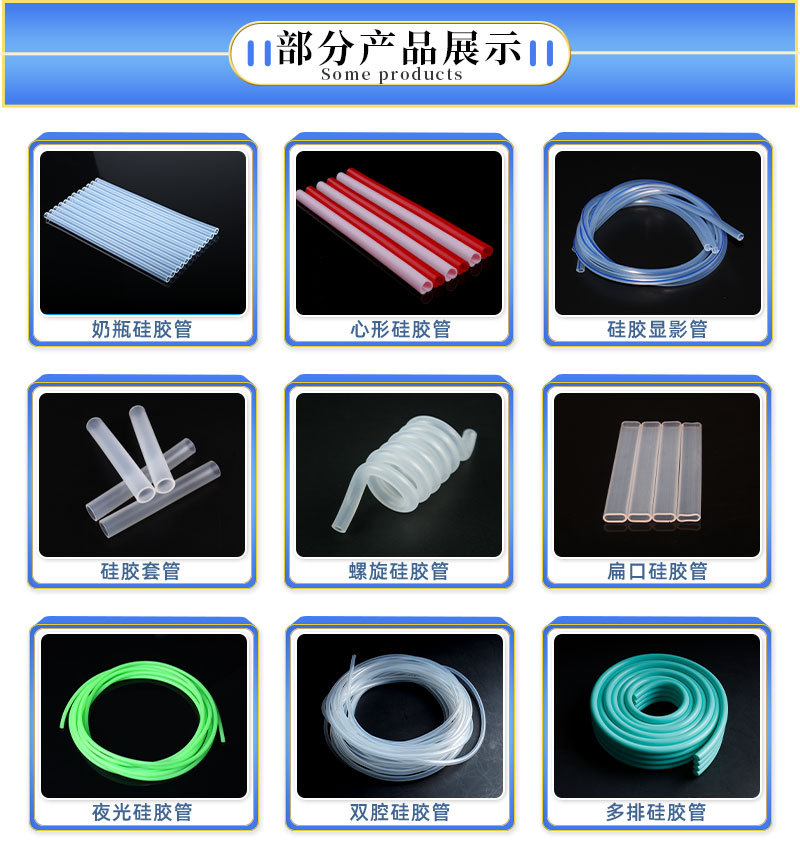

Types of Medical-Grade Silicone Tubing

Medical-grade silicone tubing comes in various types, each tailored to specific medical applications:

- Peristaltic Pump Tubing: Designed for use in peristaltic pumps, ensuring precise fluid delivery without contamination.

- IV and Infusion Tubing: Used for intravenous fluid delivery, offering flexibility and kink resistance.

- Drainage Tubing: Ideal for post-surgical drainage, providing smooth surfaces to prevent bacterial buildup.

- Respiratory Tubing: Used in ventilators and oxygen delivery systems, ensuring safe and efficient airflow.

- Catheters and Surgical Tubing: Soft and biocompatible, suitable for minimally invasive procedures.

- Laboratory Tubing: Used in medical labs for fluid transfer, resistant to chemicals and high temperatures.

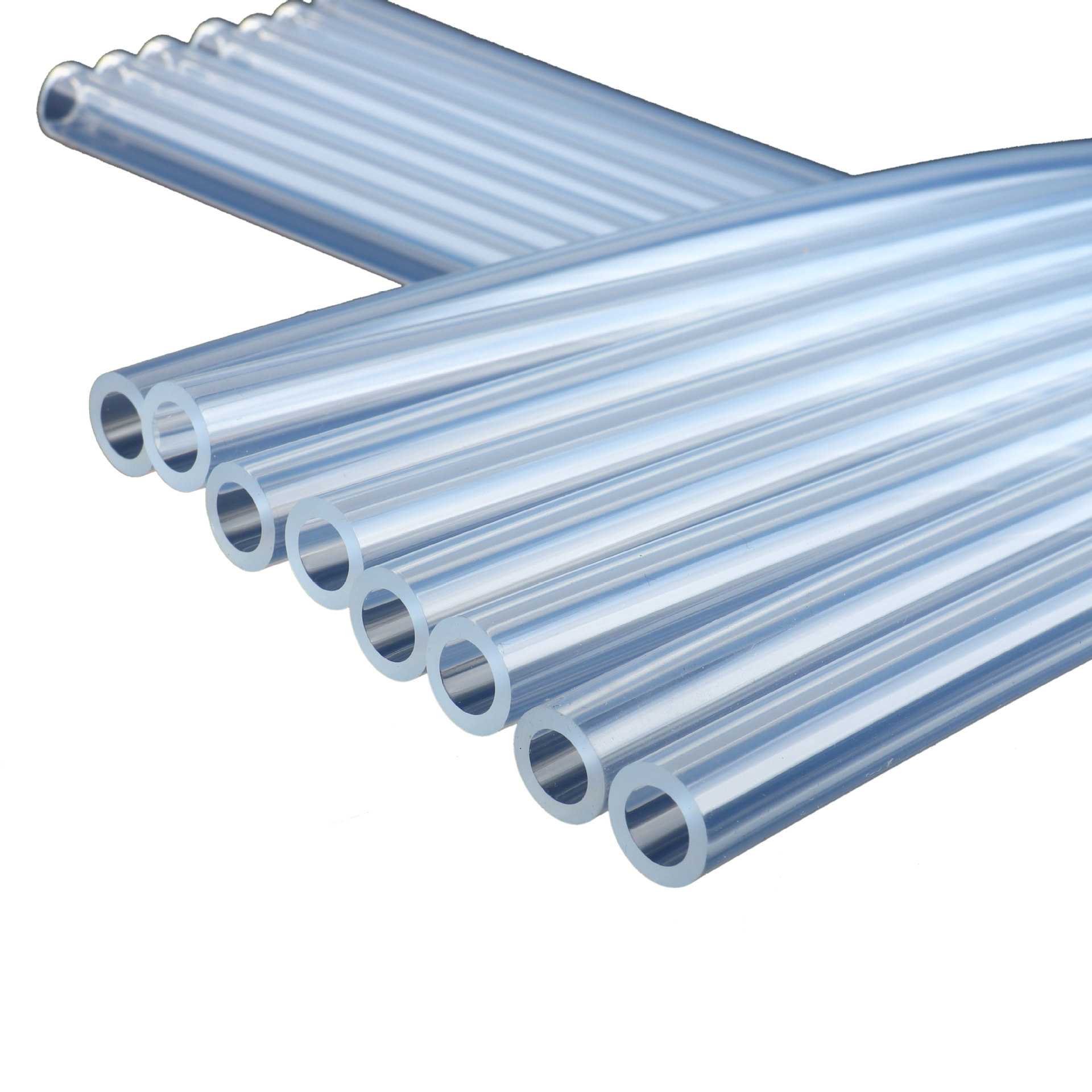

Characteristics of Medical-Grade Silicone Tubing

Medical-grade silicone tubing is known for its unique properties, making it indispensable in healthcare settings:

- Biocompatibility: Safe for contact with human tissues and fluids, meeting ISO 10993 and USP Class VI standards.

- Flexibility: Soft and pliable, yet resistant to kinking, ensuring smooth fluid flow.

- Temperature Resistance: Can withstand sterilization methods such as autoclaving, gamma radiation, and ethylene oxide (EtO) treatment.

- Chemical Resistance: Resistant to a wide range of chemicals, including acids, bases, and solvents.

- Transparency: Allows for easy visual monitoring of fluid flow.

- Durability: Resistant to wear, tear, and aging, ensuring long-term performance.

Applications of Medical-Grade Silicone Tubing

Medical-grade silicone tubing is used in a wide range of healthcare and medical scenarios, including:

- Hospitals and Clinics: For IV infusion, drug delivery, and surgical procedures.

- Pharmaceutical Manufacturing: For fluid transfer and processing in sterile environments.

- Laboratories: For chemical and biological fluid handling.

- Dialysis Centers: For blood transfer and filtration systems.

- Veterinary Medicine: For fluid delivery and surgical applications in animals.

- Home Healthcare: For portable medical devices and oxygen delivery systems.

Material Safety and Compliance

Our medical-grade silicone tubing is manufactured from high-purity silicone that complies with the following standards:

- ISO 10993: Biocompatibility testing for medical devices.

- USP Class VI: Certification for materials used in medical applications.

- FDA 21 CFR 177.2600: Compliance with FDA regulations for food and medical-grade materials.

- EU MDR (Medical Device Regulation): Meets European Union standards for medical devices.

- RoHS and REACH: Free from hazardous substances, ensuring environmental and user safety.

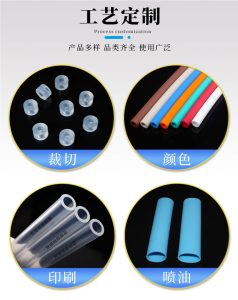

Customization Services

We offer a range of customization services to meet the specific needs of our clients:

- Material Selection: Choose from various grades of medical-grade silicone to match your application requirements.

- Size and Dimensions: Customize inner diameter, outer diameter, and wall thickness to suit specific needs.

- Color and Markings: Add color coding or printed markings for easy identification and traceability.

- Surface Finish: Options for smooth or textured surfaces to enhance performance.

- Prototyping and Testing: Develop prototypes and conduct rigorous testing to ensure compliance with medical standards.

- Packaging: Custom packaging options to ensure sterility and ease of use.

Maintenance and Care Tips for Medical-Grade Silicone Tubing

Proper care and maintenance are essential to ensure the longevity and performance of medical-grade silicone tubing:

- Cleaning: Rinse tubing with distilled water or a mild detergent after each use. Avoid abrasive cleaners that could damage the surface.

- Sterilization: Use appropriate sterilization methods such as autoclaving, gamma radiation, or EtO treatment, depending on the tubing’s specifications.

- Inspection: Regularly inspect tubing for signs of wear, such as cracks, discoloration, or stiffness. Replace damaged tubing immediately.

- Storage: Store tubing in a clean, dry environment away from direct sunlight and extreme temperatures.

- Avoid Sharp Objects: Handle tubing carefully to prevent cuts or punctures that could compromise its integrity.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for usage, cleaning, and replacement intervals.

By understanding the benefits, applications, and maintenance of medical-grade silicone tubing, healthcare professionals can ensure safe and reliable performance in critical medical applications. Whether for standard use or customized solutions, medical-grade silicone tubing offers a versatile and dependable option for modern healthcare needs.