Types of Medical-Grade Rubber Seals

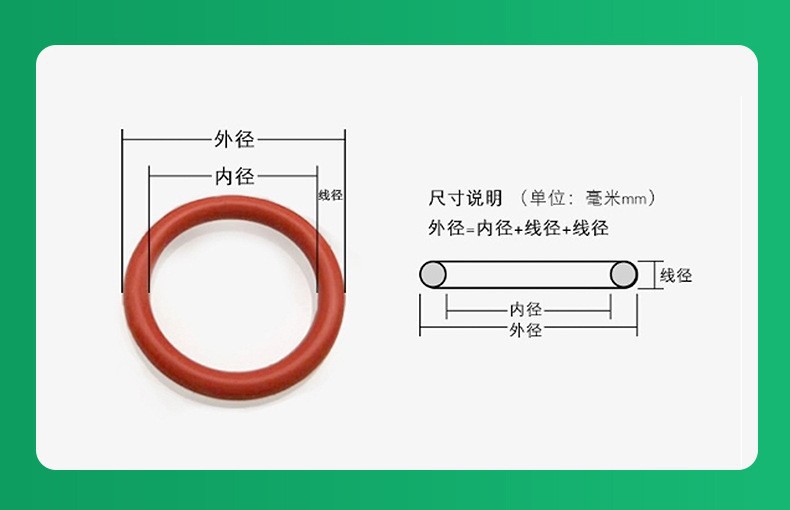

- O-Rings

- Features: Circular cross-section, high elasticity, and compression resistance.

- Applications: IV pumps, syringe connectors, and surgical instrument housings.

- Gaskets & Diaphragms

- Features: Flat or molded designs, chemical-resistant, and pressure-tolerant.

- Applications: Drug delivery systems, ventilator valves, and diagnostic equipment.

- Septum Seals

- Features: Self-sealing puncturable rubber for needle access.

- Applications: Vaccine vials, IV bags, and blood collection tubes.

- Gland Seals

- Features: Reinforced structures for dynamic motion.

- Applications: Rotary shafts in dialysis machines and imaging devices.

- Custom Molded Seals

- Features: Patient-specific geometries (e.g., prosthetics, implantable devices).

Key Characteristics

✔ Biocompatibility – Safe for prolonged contact with tissues/fluids (ISO 10993 certified).

✔ Sterilization Resistance – Withstands autoclaving, gamma radiation, and EtO treatment.

✔ Chemical Resistance – Immune to drugs, alcohols, and aggressive disinfectants.

✔ Temperature Range – Stable performance from -60°C to +250°C (-76°F to +482°F).

✔ Low Particulate Shedding – Critical for cleanroom and pharmaceutical use.

Industry Applications

- Medical Devices: Infusion pumps, ventilators, endoscopes.

- Pharma Packaging: Sterile vial stoppers, inhaler valves.

- Diagnostics: Lab analyzer seals, centrifuge lids.

- Implants: Silicone seals for pacemakers, insulin pumps.

Safety & Compliance

Our seals comply with:

✅ USP Class VI – Rigorous testing for plastics/rubbers in medical use.

✅ FDA 21 CFR 177.2600 – FDA-approved elastomers for food/medical contact.

✅ EU MDR 2017/745 – Meets EU Medical Device Regulation requirements.

✅ ISO 13485 – Quality management for medical device manufacturing.

Customization Services

We engineer seals to your exact needs:

- Material Selection: Silicone, EPDM, FKM (Viton®), or Nitrile (NBR).

- Precision Molding: Micro-tolerance seals down to ±0.005mm.

- Post-Processing: Plasma treatment for enhanced adhesion.

- Validation Support: Full documentation for FDA/CE submissions.

Maintenance & Care

- Cleaning: Use isopropyl alcohol (IPA) or mild detergents; avoid abrasive cleaners.

- Inspection: Check for cracks, swelling, or compression set monthly.

- Storage: Keep in anti-static bags at 15–25°C (59–77°F), away from ozone/UV.

- Replacement: Follow OEM lifecycle guidelines (typically 3–5 years for implants).

Why Choose Our Medical Seals?

- Zero Defect Guarantee: 100% inspected for critical applications.

- R&D Partnerships: Co-develop seals for novel medical technologies.

- Fast Prototyping: 3D-printed samples in 72 hours.

Contact us to secure FDA-compliant seals for your next medical innovation! 🚑🔬

(Word count: 398 | Keywords: medical rubber seals, USP Class VI, FDA-compliant, custom O-rings, ISO 10993)